WHAT WE DO

Urbanisation comes at a cost, a cost that can have a huge impact on the environment. While realising the importance of Sustainability, development and our dream of Morden age India, we Started with a new vision. In October 2013, through our Special Purpose Vehicle (SPV) Amdavad Enviro Project Pvt. Ltd. In partnership with Ahmedabad Municipal Corporation we started of Construction & Demolition Waste Recycling Facility. This state of art Construction and Demolition Waste Recycling Facility has operating capacity of 1000 MTPD.

WHY CHOOSE US

- Infrastructure

- Sustainable urbanization

- Construction waste recycling

- Green solutions

- NUEarth products

About Us

India moves ahead rapidly on the path of development and betterment of society. Be it the spread of urbanization or a boost in infrastructural growth, the country sets new milestones every day. With a vision to contribute to India’s all-inclusive growth through sustainable urbanization, DNP Infrastructure Pvt. Ltd. was established back in 2006.

Over the years, DNP Infrastructure has marked its strong presence among premium infrastructure construction recycling groups in Ahmedabad. Today, DNP is renowned as a prominent Indian infrastructure company engaged in the recycling of construction and demolition wastes. We at DNP Infrastructure know that urbanization comes at a cost in the form of a huge environmental impact.

As we strive to fulfill the dream of Modern India while realizing the importance of sustainability and development, we established a Construction and Demolition Waste Recycling Facility through our SPV (Special Purpose Vehicle) Amdavad Enviro Project Private Limited (AEPPL) in the year 2013. AEPPL is a 100% subsidiary of DNP Infrastructure Private Limited. A state-of-the-art Construction and Demolition Waste Recycling Facility is started in partnership with Ahmedabad Municipal Corporation (AMC).

We work toward sustainable life for future generations by offering green solutions for urbanization and development. AEPPL is committed to producing recycled goods from construction and demolition waste materials. Our recycled goods are useful for various construction related Our Construction and Demolition Waste Close Loop Recycling Facility has an operating capacity of 1000 MTPD (Metric Ton Per Day), symbolizing our dedicated effort to providing society with green solutions from waste materials.

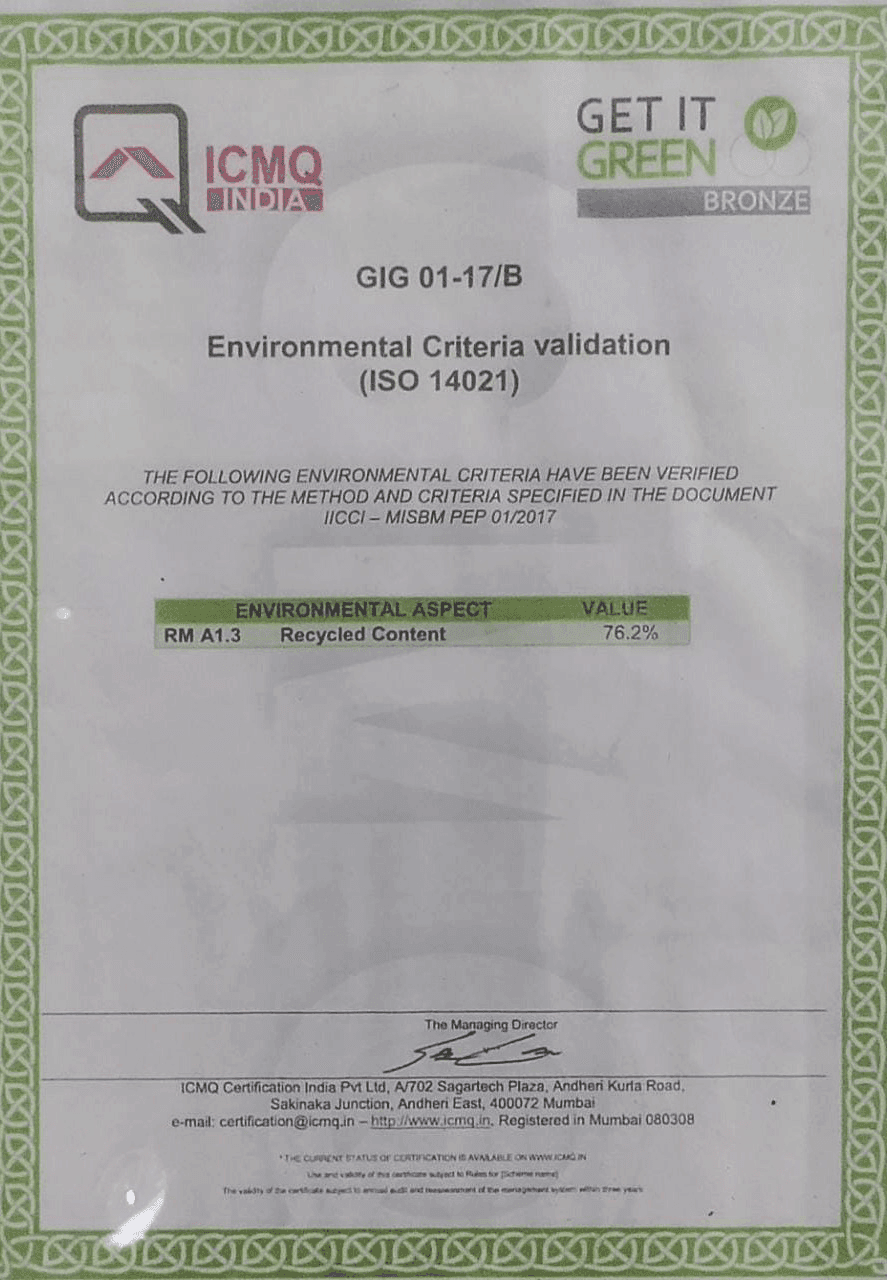

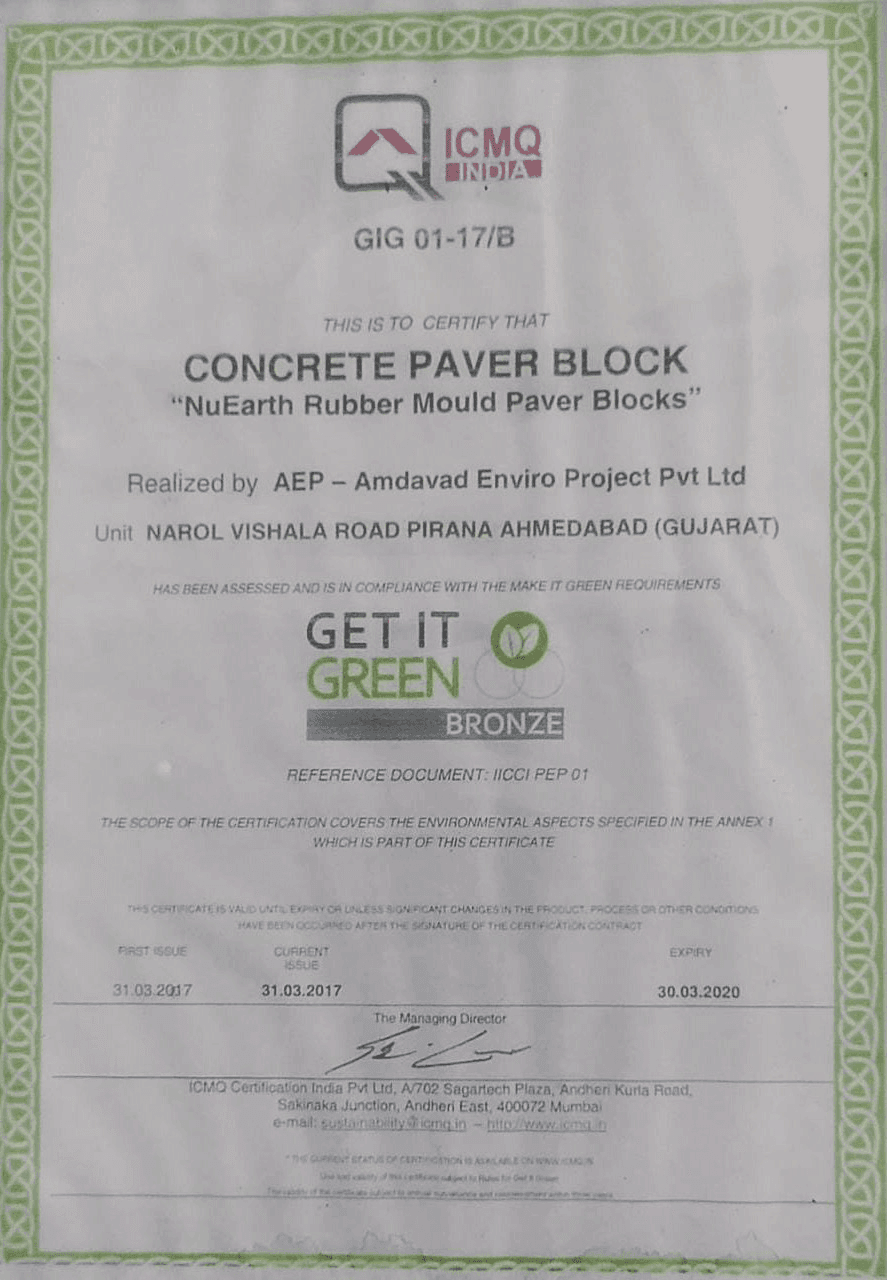

Through AEPPL, we work towards giving green solutions for urbanization and development by producing recycled finished products that can be used for construction-related activities. We have a brand known as NUEarth that reflects the vision and values of AEPPL. We just do not sell recycled products under this brand name, we want to make sure to give high-quality, reusable products for construction that have less impact on the environment and remain cost-effective.

Recycle Green Building Materials

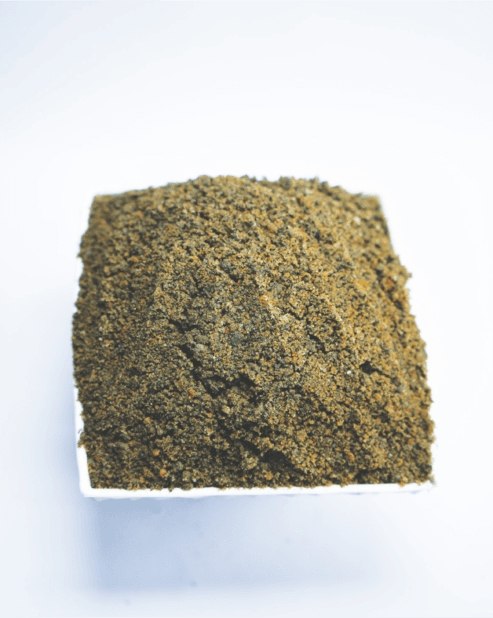

Our 20 MM aggregate, 10 MM aggregate, brick aggregate, and recycled sands are green materials from construction and demolition waste. Our recycled green building materials can save natural resources, reduce environmental impact, and increase sustainability. Our recycled aggregates and sands have multiple uses in the manufacturing and construction sectors as one of the components of concrete and filler particles.

The name Recycle Green Building Materials is given as they are made from recycled materials like construction and demolition waste. Our superior-quality aggregates ensure excellent performance in different related products. Our sand and brick aggregates have successfully provided construction and other industries with a better environmental solution. They have multiple uses, and you can always remain assured of quality.

Our state-of-the-art, closed-loop facility has cutting-edge equipment and trained staff for producing recycle green building materials. We follow the standard process from collecting and transporting construction and demolition waste to manufacturing green products.

Detailed Process for Manufacturing Green Building Materials (Recycled Products)

Collection and Transportation

It is the first step of gathering construction and demolition waste in which all such materials are collected and transported to our plant.

Feed Systems

The collected waste goes through our feed systems in the plant and prepares for screening.

Primary Screening

This phase prepares the material for primary crushing; after this stage, the material remains of equal size.

Primary Crusher

The primary crusher can crush bigger particles into smaller ones and ensure that these particles remain in the compressed form.

Secondary Crushing

It converts smaller particles into finer particles or a powder form. It is an important stage as it provides the manufacturing unit with raw materials.

Aggregate and Wash Sand

Materials for producing aggregates and sand pass through the washing process before manufacturing.

Manufacturing of Green Products

By recycling construction and demolition waste, we obtain sand and aggregates of varying sizes. We use these recycled materials to make precast green building products such as paving blocks, kerb stones and compound walls etc.

PRODUCTION FACILITY MACHINERY & TESTING LAB

These German designed Zenith machines are most versatile, manufactured in India with SIEMENS frequency control technology for producing Hollow & Solid Blocks, Pavers, Kerbstones, Flyash Bricks etc.

Our Laboratory is equipped with industry standard instruments that do product testing to ensure there is no compromise in product quality, safety and durability. Our High tech machinery ensures premium quality and industry standard outputs. We ensure that you get the best results by using our genuine recycled green products that are reliable, safe and give best results.

Achieving milestones through our Green products

OUR CLIENT

Ahmavad Enviro Project Pvt. Ltd. 2023 Develope by Silicon It Hub